Introducing Touchy Subject

This article includes sponsorship or links with referral codes which will earn me an affiliate fee. These are clearly marked with a 💵 symbol.

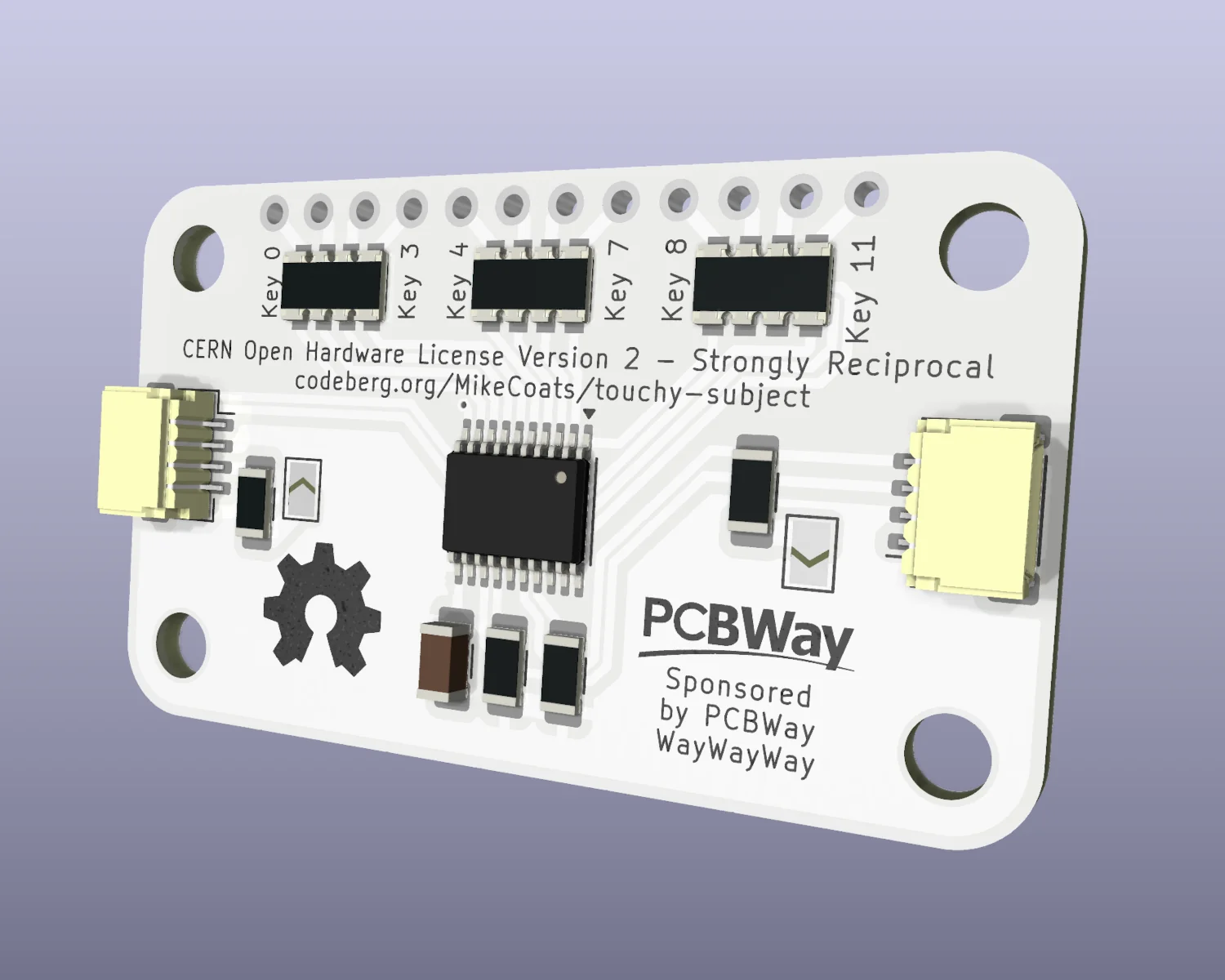

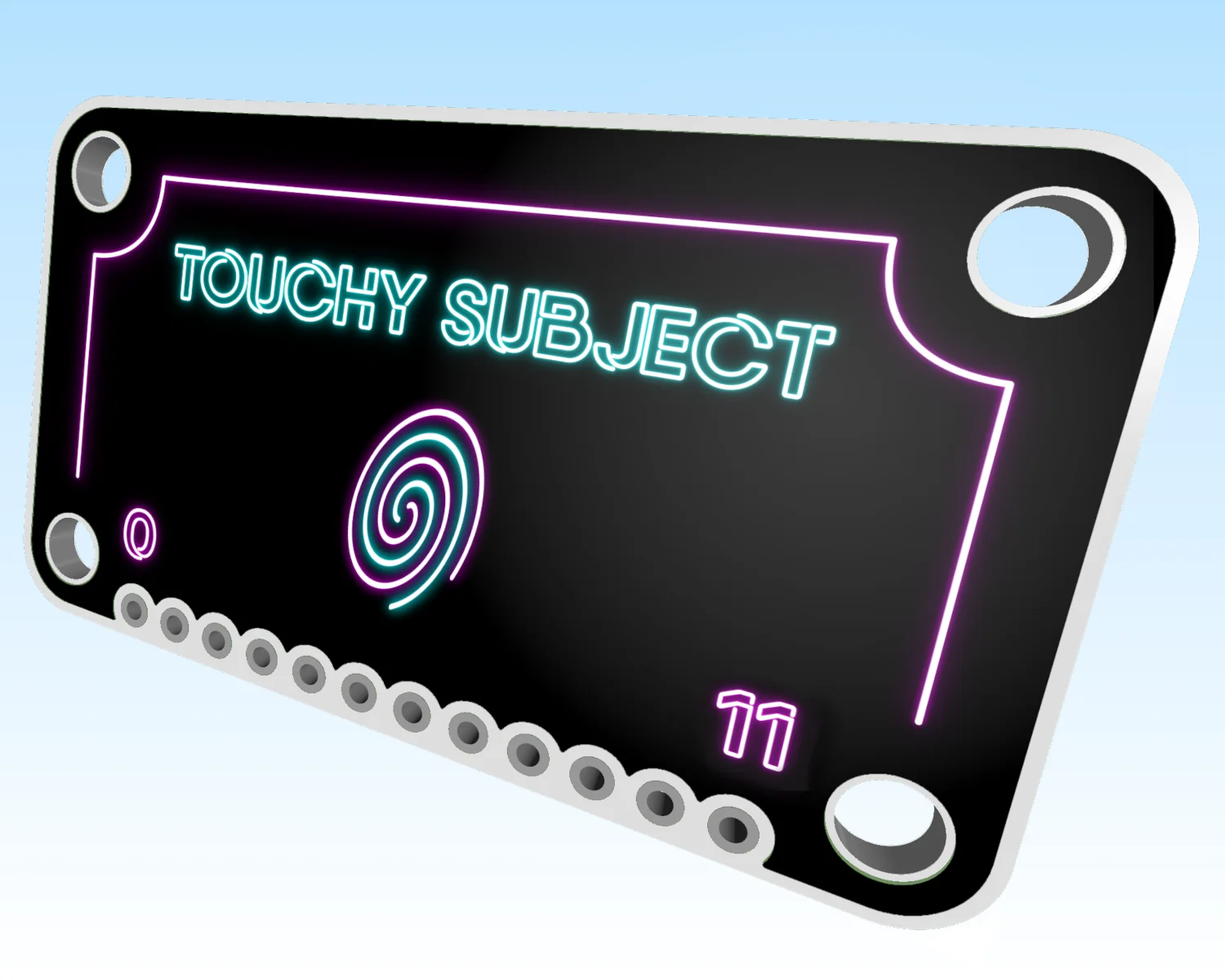

I'm proud to announce the release of Touchy Subject, a Qwiic/STEMMA QT compatible breakout board for the AT42QT2120 12-key capacitive touch sensor, the development of which has been sponsored by PCBWay💵.

The Touchy Subject is very similar to Adafruit's MPR121 breakout but with a "just about" hand solderable TSSOP-20 model of Microchip's (post-acquisition) AT42QT2120. Hopefully, this will make it easier for folks who are soldering their own boards together. The SMD other components have been kept to a decent size, so are relatively hand solderable, too. This chip can operate between 1.8 v and 5.5 v, which means that by including some JST SH connectors, the Touchy Subject is compatible with both Qwiic and STEMMA QT connection standards.

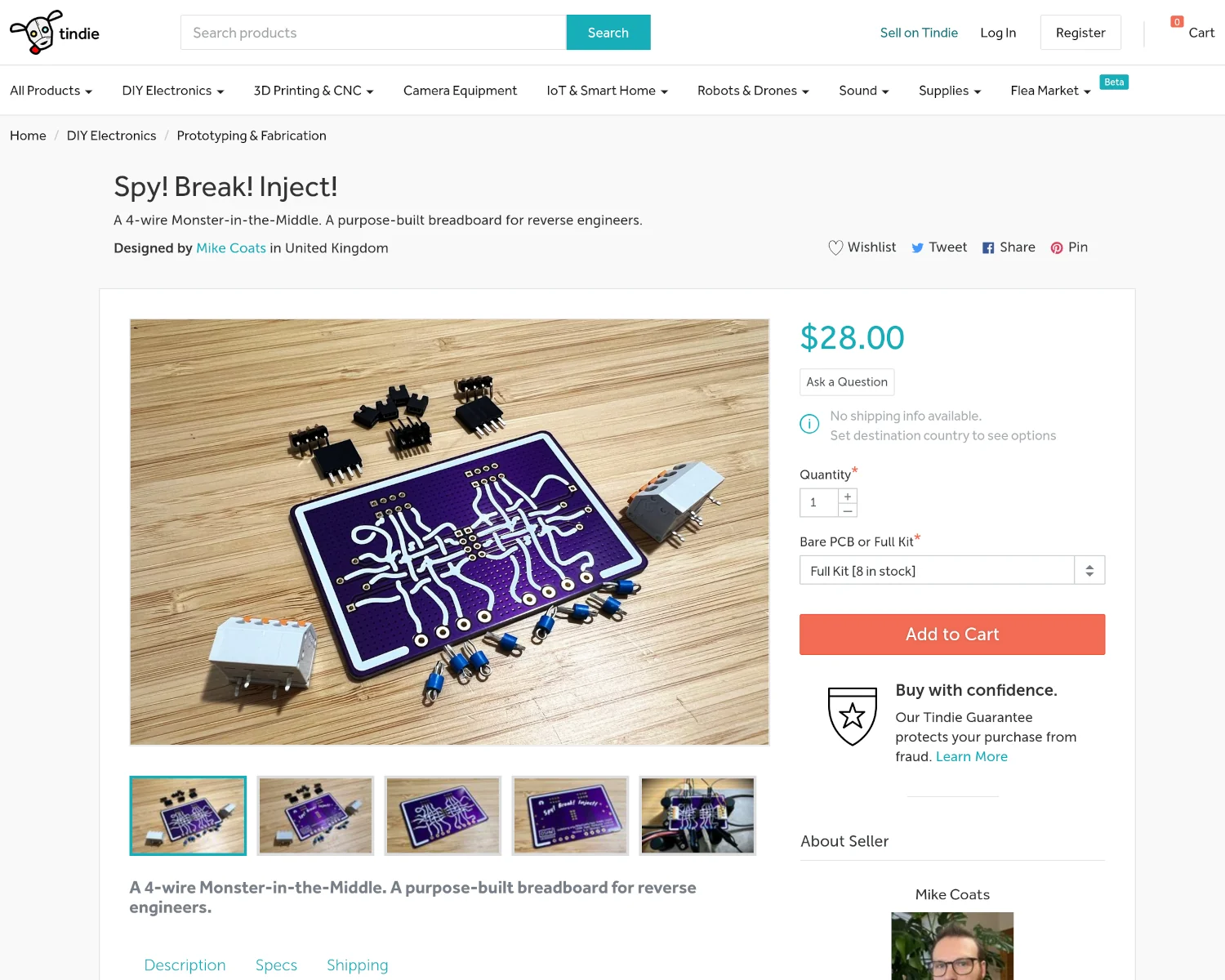

A few months ago, Emily from PCBWay💵 reached out over Mastodon to say they'd seen my Spy! Break! Inject! boards for sale on Tindie and asked if they could sponsor one of my projects.

I've had my PCBs made by a few different manufacturers in the past, but I've never tried PCBWay before, so I jumped at the opportunity. Emily was kind enough to answer the many "daft laddie" questions I had, and they even offered to cover the costs of a few services I've not had the chance to use before.

This time,

- I've chosen to use their UV print option for my PCB artwork,

- they're going to supply an SMD stencil and,

- I've asked them to manufacture the boards in a panel.

I've never had a chance to use UV printing before, so I'm excited to see how this goes. I received a PCBWay ruler in some conference swag (maybe from OHS2025?), so I've seen what their UV printing process is capable of, but I'm not sure how my on-screen renders will translate to real-world parts.

I recently picked up an MHP50 hot plate to improve my surface mount soldering, but correct paste application is still a bit of a challenge. Hopefully, a stencil will help with the accuracy and volume of my solder paste.

I'm intrigued to see what the benefit of receiving panelised boards is. I assume it will make placing the stencil easier as it will lie on a much wider surface than a solitary board, but this will remain to be seen. I figured that since I was asking for a large, thin, sheet of stencil to be delivered, I might as well get a panel since they'll be roughly the same size for shipping.

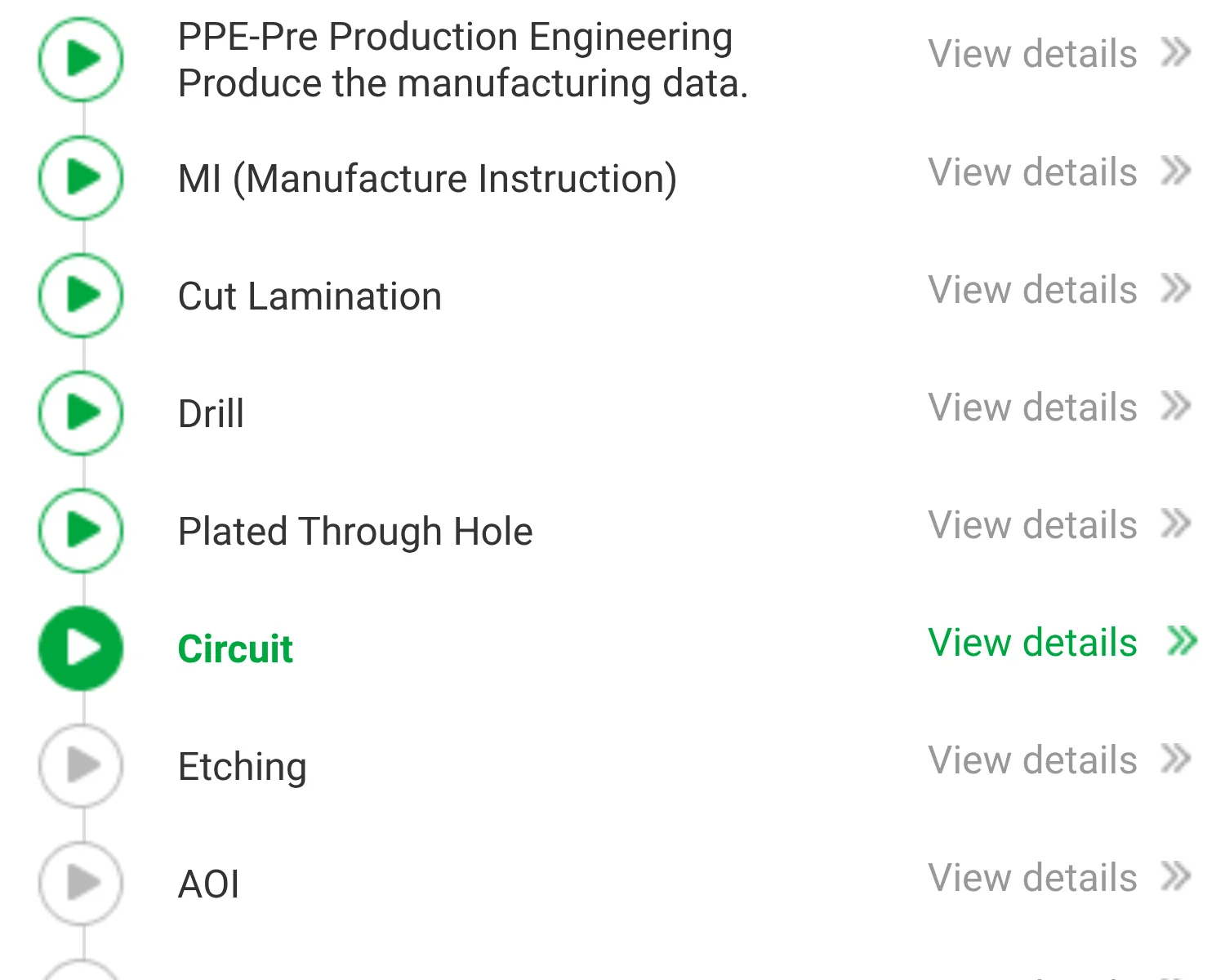

Now, I've just got to play the waiting game; refreshing manufacturing statuses and delivery trackers. Time to order the components and write some code, I suppose!

2025-09-25